- Energy saving

- Hydronic heating

- Product info

- Radiators

A guide to hydronic fan convectors in a low temperature heating system

Hydronic fan convectors: laminar vs. turbulent flow

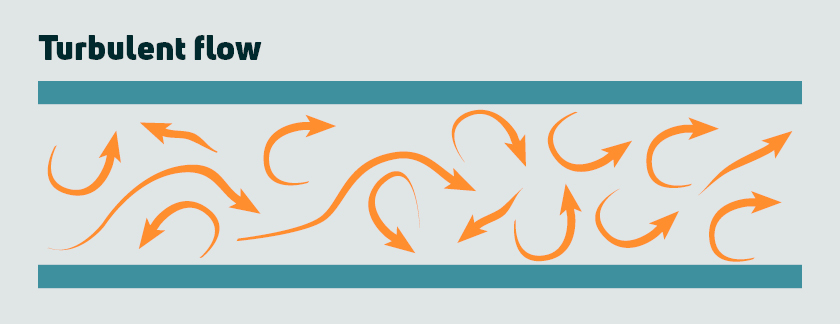

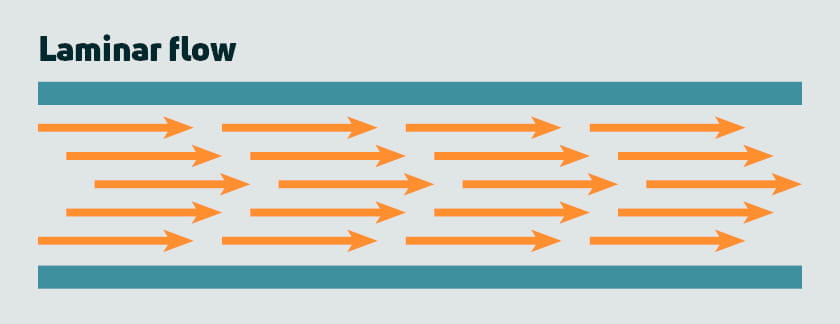

Hydronic fan convectors, such as the iVector S2 or Aquilo trench fan convectors, emit nearly 100% convection heat. To do so, they use a copper circuit or coil with aluminium fins. When running water through the copper pipes in the convector, it’s important to achieve a turbulent flow, as opposed to a laminar flow.

Turbulent flow: an irregular flow with a continuous change in the magnitude and direction of the flow. Characterised by a high velocity.

Laminar flow: a smooth, streamlined flow characterised by a lower velocity.

“The turbulent flow enables the water to better transfer the heat to the pipe. That’s why flow control is so important when it comes to hydronic fan convectors. If the flow is too low, the required heat output will simply not be achieved” explains Niclas Schubert, Vice President of Sales at Purmo.

It also speaks to why hydronic fan convectors are such a good match for low temperature heating systems. Since the heat output is, simply stated, calculated by multiplying flow and temperature, it follows that if you lower the temperature, you increase the flow and vice versa. So lowering the temperature helps to ensure the required turbulent flow that hydronic fan convectors demand to produce the necessary heat emission The fans in turn help to increase the power output so that you don’t need a larger unit to meet the heat demand.

Accurate measurements for hydronic fan convectors

To guarantee that the calculated output matches the actual power output, accurate measurement is of the utmost importance. “That is why at Purmo we measure fan convectors and trench fan convectors both in laminar and turbulent flow”, says Jan Samuelson, Product Manager at Purmo. “This gives us the true power output. Most suppliers tend to use test results for their calculations, assuming that the unit is in turbulent flow, but then you risk getting insufficient power output when it’s actually in laminar flow”.Niclas adds: “Moreover, suppliers sometimes increase the flow in the hydronic fan convectors more than necessary. When you increase the turbulency, you also increase the power output. It allows the heat transfer from the water through the pipes to the fins to increase up to 20%. This means you can have a smaller fan convector emitting the same amount of energy. However, the cost of running the convector increases substantially as you need a larger circulating pump to drive the system. Consequently, the electrical consumption goes up, which counteracts the energy savings that you are trying to achieve with lower supply temperatures.”

“When talking about the pump and energy savings by the way, it’s important to point out another nuance. Pump manufacturers sometimes state that you can reduce energy consumption by 40%. That’s true but only for the electrical consumption of the pump. Not for the system. The pump represents about 4 to 5% of the total energy consumption in a heating system. So you reduce 40% of 5%, not 100%.”

The importance of the return temperature

In addition to the correct flow, it’s also very important to consider the right supply and return temperature. “Especially the return temperature is often not taken into account by suppliers. However, it’s important to align supply and return temperatures if we want to create energy-efficient heating and cooling systems. This means the power output of fan convectors should no longer be calculated according to the old EN422 standard. You need accurate measurements on the actual convector in the right system temperatures. So before stating the power output of our hydronic fan convectors we have realised a great amount of measurement work”, says Jan.“If the actual return temperature differs from the theoretical one, you risk creating a laminar flow and a much lower power output. It causes problems when you have high supply temperatures and low return temperatures. The solution then is to lower the supply temperature so that you create a turbulent flow and align the system with the heat emitter. As a system supplier we recognise the importance of aligning all elements and controlling both supply and return temperature to ensure the right power output. Our accurate measurements in laminar flow are the best basis for this.”

Niclas adds: “The return temperature is so important. Especially if you have a condensing boiler, which is still the case in most buildings. You need to be able to condensate. If the return temperature is too high, the system is not as efficient as it would be with a low return temperature.

To guarantee that the calculated output matches the actual power output, accurate measurement is of the utmost importance. “That is why at Purmo we measure fan convectors and trench fan convectors both in laminar and turbulent flow”, says Jan Samuelson, Product Manager at Purmo.

The right pipes for your hydronic fan convectors

Creating the right flow to ensure optimal heat output in a hydronic fan convector is not only linked to the supply temperature, the pipes also play a vital role. A small pipe reduces the flow, while a larger pipe increases it. The pump creates the pressure, but the actual flow is determined by the resistance experienced by the water. More resistance means a low flow, while a low resistance creates a larger flow.The pipe network is therefore an important factor both in new build and renovation projects. However, unlike new builds that allow you to freely select the right pipes, a renovation project can be challenging in that respect. “First of all you need to calculate the new heat demand, because you might also renovate other aspects such as the windows, insulation, ventilation, etc. Based on the new heat demand, you can assess if the current convectors are still the right size. Since you reduced the demand, chances are that they are oversized. The logical step is to reduce the flow, but you actually need to calculate a new flow for the convector, otherwise you risk creating a laminar flow,” says Niclas. “If the new flow is very high because you lower the temperature in the system, you need to consider the pipes as well as they might be too small. An increase in flow in a low temperature heating system puts a strain on the existing pipe network.”

If we want to create energy-efficient systems, we need to do it right.

“When switching to a low temperature system it’s not just to the temperature you need to consider. Also the flow and pressure from the pump are important factors. When the temperature goes down, the flow goes up but the pressure from the pump also needs to go up of you want to keep the same pipes. Unfortunately, the pipes, together with the vales and the hydronic balancing of the system are often forgotten.”Jan adds: “When you renovate and want to create an energy-efficient system, you must take into account all parameters in the design of a new heating and cooling system with hydronic fan convectors. Otherwise, the system runs inefficiently and you’re unable to enjoy the promised savings. If you’re switching to a new energy source, you balance the system so that it delivers energy with the corresponding supply and return temperature. It’s then really important that the fan convector is designed in the same way so that both supply and return temperatures are fixed and the power output corresponds to those parameters. Otherwise, the system won’t be able to deliver enough power in the middle of winter. Another reason why having true value in laminar flow is so important. If want to create energy-efficient systems, we need to do it right.”

Flow control in hydronic fan convectors with the right valves

Another important piece of the puzzle to ensure flow control is using the right kind of valves. “To ensure optimal flow to the hydronic fan convectors you need balancing valves that allow you to preset and measure the flow”, explains Niclas. “A variable speed pump is not the answer here. You need to make sure you can control the flow of every individual convector in the system. A control valve with an actuator doesn’t suffice. You must have a valve that has a pre-setting function, such as the Flamingo valve insert or the Evoflow valve.”For HVAC specifiers and installers, the implementation of hydronic fan convectors in modern, energy-efficient heating systems thus means many things to consider. That also includes the comparison of fan convectors from different suppliers. Jan comments: “When Delta t is very high and you have a low flow in the system, it’s important to evaluate whether you are in turbulent flow. That determines whether you can use the supplier’s stated power output. The power output of our fan convectors tends to be a bit lower than others, but that’s because we use true measurements that reflect the right power output in laminar condition. For HVAC professionals it’s important to understand this difference so that they can compare apples to apples and design the system with the right flow.”

Conclusion

By sharing essential know-how, we have tried to convey the importance of flow and temperature control, in particular with regard to fan convectors in low temperature systems. Various factors play an important role such as the right supply and return temperature, fitting pipes and the right kind of valves. Considering all these elements will help to facilitate the switch to a low temperature heating system. Moreover, accurate measurements lay the foundation for HVAC professionals to make the right choice based on the true power output of the fan convector. This is the only way to guarantee both comfort and efficiency year-round.

If you have any questions about the implementation of our hydronic fan convectors, don’t hesitate to reach out to our experts. We will be happy to help you make the best choices for your project.

Discover our entire range of hydronic fan convectors